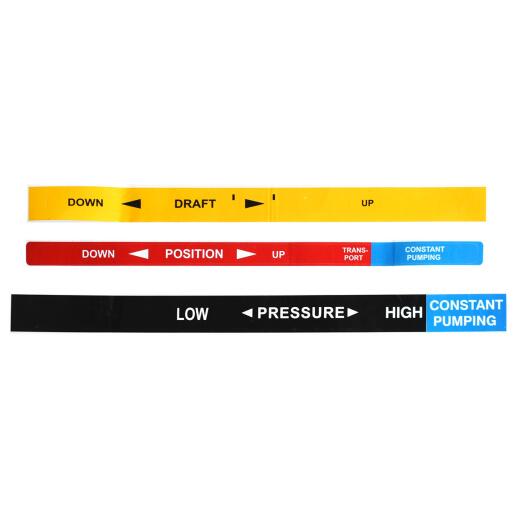

Barometric Draft Control Dampers are designed for Oil or Gas Furnace applications. Oil Furnaces use a 'Single-Acting' Draft Control to maintain a consistent vent draft by counteracting the negative pressure changes caused by temperature and barometric pressure, as well as, wind effect.Gas Furnaces use a 'Double Acting' Draft Control.It opens inwardly to maintain a uniform draft. Draft control does not work based on the angle of the front of the tractor but rather on the pull of the implement, normally a plow, via the top link connection (where the big spring is). It is designed to keep the plow at an even depth and to allow it to rise if it hits an immovable object. Draft control is the automatic adjustment of the three-point hitch when using tillage equipment such as a moldboard plow, ripper or cultivator. This can either be done by sensing the amount of forward pressure on the three-point top link, called top link sensing, or by sensing the rearward pull on the lower links called lower link sensing.

Draft Control Draft must remain constant for proper operation and efficient fuel consumption in heating appliances. When draft control is used in oil, gas, and/or coal-fired heating appliances, fuels are.

With revolutionary advances such as our EC-Flow™ technology and Truline™ fan construction, US Draft Co. is solving the challenges presented by the next generation of appliances. At US Draft Co., we understand the complex issues presented in modern day appliance venting and we are ready to assist you in your venting needs.

US Draft Co. has a full line of mechanical draft inducers, variable volume flue dampers and related controllers.

With revolutionary advances such as our EC-Flow™ technology and Truline™ fan construction, US Draft Co. is solving the challenges presented by the next generation of appliances. At US Draft Co., we understand the complex issues presented in modern day appliance venting and we are ready to assist you in your venting needs.

US Draft Co. has a full line of mechanical draft inducers, variable volume flue dampers and related controllers.

Draft regulators or barometric dampers are devices used to regulate the draft on oil-fired furnaces, boilers, and water heaters. Yes, even water heaters! I can’t tell you how many times I have seen water heaters installed without a draft regulator installed, and a stack temperature over 900° or 1,000° F, and a draft over the fire that (as we used to say) would suck the chrome off a bumper. Well, that’s when car bumpers had chrome.

To be sure you understand me, the draft regulator I am referring to here is used only on oil-fired heating equipment, not on gas-fired equipment. That’s a whole different animal.

On oil fired equipment, the draft regulator is typically a round device with a swinging door, which will only swing one way, and with an adjustable weight on it, which will allow you to adjust it to control the draft. You adjust the weight to control the amount of the opening of this damper which in turn controls the amount of excess air that can enter the flue and chimney when the oil burner is operating. In this way you adjust the draft over the fire in the appliance.

To be certain of the terminology, the straight run of the tee is called the ‘run” and the 90 degree connector, in the middle, is called the ‘bull.” The draft regulator is to be inserted into the ‘bull” of a smoke tee between the heating appliance and the chimney, and usually a minimum of 18″ from the appliance. How many times have you seen it installed in the ‘run” of the tee? We used to install the tee so that the flue pipe would make a right angle from the appliance to the chimney, remember? It was so convenient to check and clean out the chimney base, but it was wrong! Well, we were all wrong. There are so many still like this in the field, don’t leave it like this!

Why do you need a draft regulator at all? Air that is used for combustion is called combustible air. That air may be in the boiler room or delivered by mechanical means, but it is still combustible air. This air is combined with the fuel and is part of the combustion process. The gases that are produced must be discharged back to the outside environment. The gases moving through this process is called the draft.

Draft Control Wood Stove

Too much draft will decrease the efficiency of the heating appliance, increasing cost, but it will also increase chimney temperatures (stack temperature) to an unsafe level. Too little draft can result in incomplete combustion, soot, puff backs, and in an extreme case, carbon monoxide. Since the chimney draft varies greatly, we need a way to stabilize it. This is the job of the draft regulator.

Let’s say that you measure the draft July and get a reading of -.04 in the smoke pipe. Do you think that reading would be the same in February without the help of the draft regulator? The winds and the outdoor temperature all affect the draft. Also a second unit using the same chimney as the heater, say a water heater, will affect the draft. Also, a major problem to affect draft is outside boiler rooms. In many homes the boiler room is in the back of the house and accessed through a separate door from the house. I have never seen an outside boiler room with any more space in it than what the heating appliance needs. Most, if not all, of these rooms had outside air vents when they were first designed, but over the years they have been closed off, had a new roof installed over them or just simply removed because no one knew what they were there for. When you do your testing in the summer, you will leave the boiler room door open. When I did my testing however, as uncomfortable as it may be, you need to close the door. If you don’t, things will change. Generally, the draft regulator is set to the lowest draft that gives good combustion and proper oil burner operation. Higher draft will waste money for your customer.

Typically, we try to attain draft readings of 0.02 0r 0.03′ WC over the fire and 0.04 to 0.05″ WC in the breech. You can’t verify these readings without test equipment. Don’t forget that changing the draft will affect the CO2 readings you will get, so test, my friend, test. While these draft readings are typical, there are units that operate in a positive draft mode. Therefore, it is very important to read the instruction manual that is supplied with every new unit. The manufacturers will send you any instructions you need for their appliance just ask them for them.

Draft Control Kit

Draft Control Damper

A lot is to be said about combustible air and how much is needed and where it comes from, but that’s for another time.